ENGINE BUILDING

Building engines and carrying out the machining of components for engines is our core business. With years of knowledge and experience to call apon, we are able to work on just about any engine where there are parts and specifications available for machining and assembly. There are also the engines that we specialise in from Ford, Jaguar and Rover, which can be found in our “ENGINES” section in more detail.

Whether you would like us to fully build your engine, or you would prefer us to assemble a ‘kit’ of components that we have machined to your specifications, we can help. Our range of services and machining facilities we can provide include:

CYLINDER HEAD SERVICES

Cylinder Head Refacing / Skimming – cast iron or alloy cylinder heads.

Valve Refacing – to original or custom specifications, including 3 angles.

Valve Seat Replacement – removal of material for a seat, or replacement of an original seat, including unleaded conversion.

Valve Seat Cutting – to original or custom specification, including 3 angles.

Valve Spring Testing – check potential for re-use or adjustment.

Valve Guide Replacement – worn or cracked guides can be replaced or sleeved.

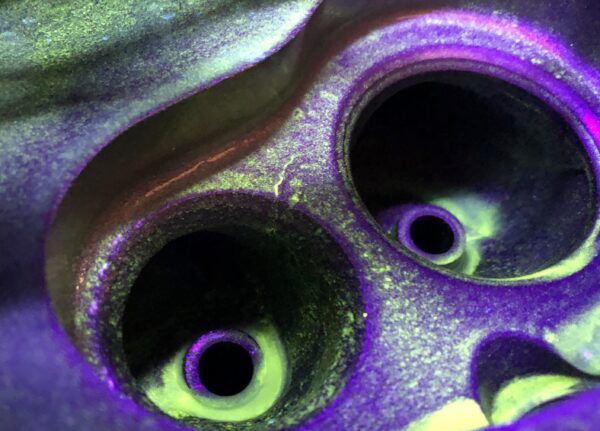

Cylinder Head Porting and Gas Flowing – for performance applications, with in-house flow bench testing available.

Hardness and Pressure Testing – check for cracking, or hardness, in alloy or cast iron cylinder heads.

Cylinder Head Assembly – once machining works are completed, we can re-assemble the head and make ready for refitting.

Head Gasket Sets – we can provide a full head gasket sets to go alongside your freshly refurbished cylinder head.

CYLINDER BLOCK SERVICES

Block Skimming / Resurfacing – removal of corrosion, refacing after repair works or fitting of liners. Both inline or V blocks.

Cylinder Boring – re-bore for oversized pistons of both inline and V blocks.

Honing Cylinder Bores – hone to precise dimensions and finishes for your pistons.

Installing Cylinder Liners – where a cylinder bore has reached its maximum size or is corroded, a liner can be fitted to allow the use of a standard piston again.

De-Rust Process and Cleaning – chemical dip treatment for removal of corrosion on the inside and outside of components.

Main Bearing Line Honing – restoration of the centre line and dimensions of the main crankshaft housings for replacement or damaged/repaired/uprated main caps.

Block Pressure Testing – checking for leaks into cooling system and oil paths.

CRANKSHAFT SERVICES

Crankshaft Grinding – re-grinding crankshafts to accommodate under-sized main and/or big-end bearings – up to 48″ in length.

Crankshaft Lapping – cleaning up the main and/or big end journals of your crankshaft to re-use the current bearing sizes.

Clean Out Crankshaft Sludge Traps – typically on Jaguar 6-Cylinder crankshafts this process removes the ‘sludge bungs’ and cleans the traps inside where oil residue and debris accumulates over time.

Magnetic Particle Inspection – crankshaft crack detection allows us to assess fully the condition of the crankshaft into the remotest recesses.

Crankshaft Modification for Revised Oil Seals – where available, revised rear oil seal assemblies may require minor crankshaft modification.

OTHER SERVICES

Fuel Injector Testing and Cleaning – Asnu injector testing rig with provision for most injector types (excluding Diesel and GDi types). Injectors can be cleaned and tested with spray-pattern check and flow rate report.

Vertical and Horizontal Cylinder Honing – motorcycle engine single/twin cylinder barrels can be honed for new pistons.

Ultrasonic Thickness Testing – for measuring available material in areas such as cylinder walls.

Surface Roughness Testing – for checking specific finishes for cylinder head and block where gasket manufacturers may provide a tolerance.

Dynamic Internal and External Balancing – all rotating components from front-to-back can be assembled and fine-balanced. Clutch, flywheel, crankshaft and pulleys as a start point, but also pistons, and con rods for completeness. In-line and V engines using in-house manufactured counterweights.

Connecting Rod Alignment – accurate straightening of bent con rods is sometimes possible for rarer and hard to obtain types.

Magnetic Particle Inspection / Crack Testing – testing of steel and cast iron components from cams, crankshafts and con rods, to flywheels and cylinder heads.

Bead / Grit Blasting – clean-up of older components, removing light corrosion, in-grained dirt deposits or old paint, to leave a smooth finish on the surface ready for treatment.

Avery Hardness Testing – to identify soft areas in surfaces, for example where cylinder heads have overheated and the alloy has become compromised.

Camshaft Profile Checking – recording of the specific profile of an existing or unmarked camshaft. Useful in the checking of regulated camshafts in race series.

Airflow Bench Testing – porting and gas flowing of cylinder heads can achieve a higher degrees of accuracy and repeatability when the flow bench is used.

MIRA Vacuum Testing – for checking of valve-sealing on heads during assessment and during preparation works.

Engine Dynamometer – Schenk Engine Dynamometer with full data logging and environmental controls. Fuel injection and Carburetted engines.

MIG and TIG Welding – on-site welding facilities for the repair of components and construction/fabrication of parts for example bespoke intakes/exhaust.